3D FloTrix® microSPIN 6-channel micro-bioreactor for Scientific Research Hits the Market Microsystems demonstrate bright prospects

- Categories:Company News

- Author:CytoNiche

- Origin:CytoNiche

- Time of issue:2022-11-16

- Views:841

(Summary description)Clickthevideotoseethatmicrosystemsdemonstratebrightprospects[Officiallyreleased|3DFloTrix®microSPIN6-channelmicro-bioreactor]Organoidtechnologyhasawiderangeofapplicationsindiseasemodeling,drugscreenin

3D FloTrix® microSPIN 6-channel micro-bioreactor for Scientific Research Hits the Market Microsystems demonstrate bright prospects

(Summary description)Clickthevideotoseethatmicrosystemsdemonstratebrightprospects[Officiallyreleased|3DFloTrix®microSPIN6-channelmicro-bioreactor]Organoidtechnologyhasawiderangeofapplicationsindiseasemodeling,drugscreenin

- Categories:Company News

- Author:CytoNiche

- Origin:CytoNiche

- Time of issue:2022-11-16

- Views:841

Click the video to see that microsystems demonstrate bright prospects

[Officially released|3D FloTrix® microSPIN 6-channel micro-bioreactor]

Organoid technology has a wide range of applications in disease modeling, drug screening, precision medicine, organ development, and regenerative medicine, to name a few. Agitated bioreactors provide fluid stress for cell culture, address the issue of inadequate contact between cells and oxygen during organoid culture, and demonstrate high application value in certain organoid models, benefiting the development of organoid technology. However, in addition to fluid stress, other factors, such as long test cycle, complicated screening of culture conditions and expensive culture medium, also impose significant obstacles to the development of organoids, gene therapy, cell medicines, and other scientific study.

Based on the leading industrial demand exploration and strong technical research and development (R&D) capabilities, CytoNiche has released 3D FloTrix® microSPIN 6-channel micro-bioreactor in order to address industry pain points and provide efficient, stable, and cost-effective solutions for the development of cell drugs and organoid, virus packaging, plasmid transfection, gene and protein expression, tumor research, and other fields.

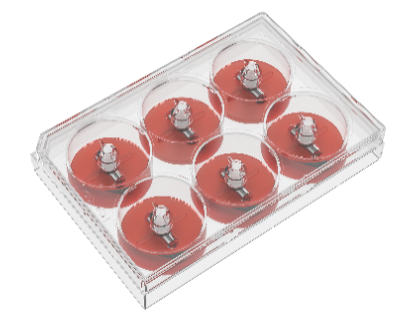

Utilizing an electrically driven magnetic agitated device in conjunction with a 3D FloTrix agitated cell culture plate, 3D FloTrix® microSPIN 6-channel micro-bioreactor realizes synchronous exploration and verification of multiple process conditions, and ensures the achievement of many core functions of dynamic biomimetic environment, while minimizing R&D costs, satisfying the relevant needs of scientific research exploration (universities/hospitals), clinical research (hospitals/testing companies) and development application (pharmaceutical companies/CRO).

[Product Features | 3D FloTrix ® microSPIN 6-Channel Micro-bioreactor]

3D FloTrix® Agitated Cell Culture Plate

✧1.Dynamic bionics

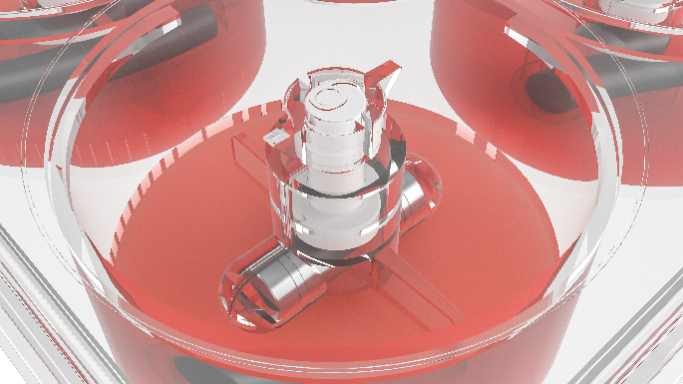

Magnetically driven impeller generates tissue mechanics microenvironment

✧2.Microsystems

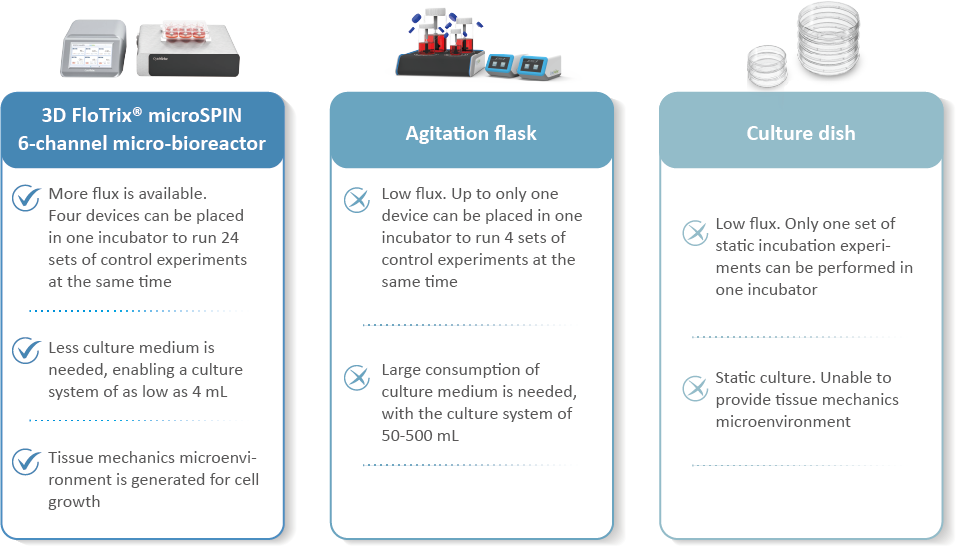

Dynamic cultivation in as little as 4 mL microtube facilitates effective R&D cost reduction

✧3.Disposable sterile consumables

Medical-grade PS materials ensure biocompatibility

3D FloTrix® microSPIN 6-Channel Micro-bioreactor

✧1. Parallel processing of six conditions

R&D cycle is significantly shortened through simultaneously exploring and verifying six process conditions

✧2. Multi-mode agitation

Cyclic agitation, constant agitation, and intermittent agitation

✧3. Ten process programming

Ten processes can be preset to achieve one-touch operation with convenience and efficiency

✧4. Customized multi-hole linkage

Support the function of hole location association to achieve parallel process control

✧5. High precision control

Research control system regulates the minimum steady-state error of rotation speed within ± 1 rpm to ensure the stability of experimental results

✧6. Anti-magnetic field interference technology

Self-developed interference technology of anti-magnetic field enables each hole to operate independently without interference with others

✧7. Composite heat dissipation design

Highly conductive materials are applied, and independent heat dissipation air ducts are available to maintain a steady-state environment for cell growth

✧8. Mini model

The overall height of the mini model is only 75 mm, with occupancy volume of 0.05 m3. Four microSPIN reactors can be placed in a 170 L incubator, enabling the performance of 24 sets of control experiments at the same time

✧9. User-friendly design

Flat data line is designed to make it easy to pass through the gap;

30 degree inclination window is designed to facilitate standing observation

[Product Advantages | 3D FloTrix® microSPIN 6-Channel Micro-bioreactor]

[Application | 3D FloTrix® microSPIN 6-Channel Micro-bioreactor]

In addition to organoid culture mentioned above, 3D FloTrix® microSPIN 6-channel micro-bioreactor is also widely used in 3D cell culture, viral packaging, plasmid transfection, gene, protein expression, and tumor research.

① 3D Cell Culture

3D FloTrix® 6-channel micro-bioreactor conforms to the CytoNiche standardized 3D FloTrix® cell culture process, ensuring the continuity of the cell culture process from development to production.

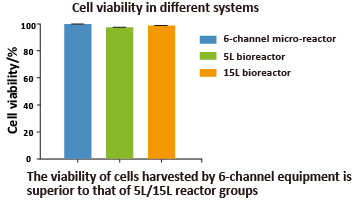

● Data comparison between 6-channel bioreactor and 5L/15L bioreactor (UCMSC)

The cell culture effects of 6-channel micro-bioreactor are proved to be essentially the same as that of 5L/15L bioreactor, achieving more than 10-fold of cell proliferation.

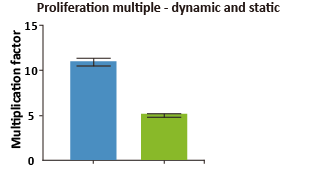

● Data comparison between 6-channel micro-reactor and 6-well plate static culture (UCMSC)

Data and experiments have shown that dynamic culture of MSC cells with microSPIN 6-channel bioreactor is better than static culture, ensuring significant improvements in cell proliferation multiple, cell diameter and viability.

② Gene Therapy

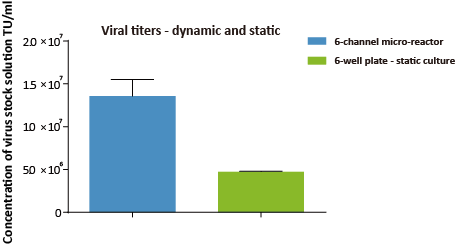

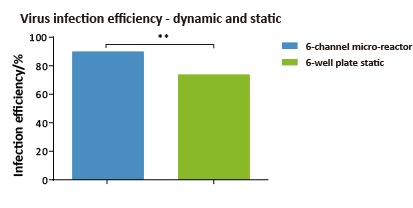

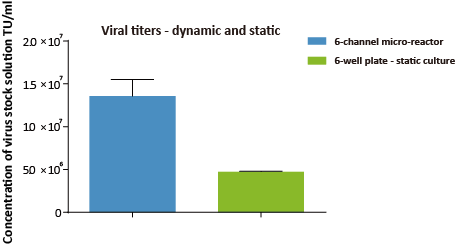

293T cells are cultured in a 6-channel micro-reactor and a 6-hole plate in three dimensions, respectively, and the infection efficiency and virus titer are calculated 72 hours after infection of the cells.

The experimental results demonstrate that the infection efficiency of 6-channel micro-reactor (reaching 90%) is superior to that of 6-hole plate static culture (infection efficiency of 74%) after 72 hours of viral infection under the same cell and micro-carrier inoculation conditions; additionally, the concentration of viral stock solution in the harvested supernatant of 6-channel micro-reactor is higher than that of 6-hole plate static culture.

3D FloTrix® microSPIN 6-channel micro-bioreactor, a self-developed unique product of CytoNiche, has focused on scientific research users and innovative research from the beginning of its development. It is believed that the marketing and application of this instrument will revitalize important industries such as cell drug R&D, organoid R& D and gene therapy, accelerate the industrialization process of biopharmaceuticals, and foster the growth of life sciences and pharmaceutical industry, kicking off a new phase in the development of cell industrialization.

【CytoNiche】

Beijing CytoNiche Biotechnology Co., Ltd. was established by the research team of Professor Du Yanan from Tsinghua University School of Medicine, and was jointly established by Tsinghua University through equity participation. The core technologies were derived from the transformation of scientific and technological achievements of Tsinghua University. CytoNiche focuses on building an original 3D cell "smart manufacturing" platform, as well as providing overall solutions for the 3D microcarrier-based customized cell amplification process.

CytoNiche's core product, 3D TableTrix® Microcarrier Tablet (Microcarrier), is an independent innovation and the first pharmaceutical excipient grade microcarrier that can be used for cell drug development. It has obtained the certificate of analysis from relevant authoritative institutions such as National Institutes for Food and Drug Control, and obtained 2 qualifications for pharmaceutical excipients from the National Medical Products Administration (CDE approval registration number: F20210000003, F20200000496). Moreover, the product has obtained the DMF qualification for pharmaceutical excipients from U.S. FDA (DMF: 35481).

Products and services of CytoNiche can be widely used in the upstream process development of gene and cell therapy, extracellular vesicles, vaccines, and protein products. At the same time, it also has broad prospects for applications in the fields of regenerative medicine, organoids, and food technology (cell-cultured meat, etc.).

Our company has a R&D and transformation platform of 5,000 square meters, including a CDMO platform of more than 1,000 square meters, a GMP production platform of 4,000 square meters, and a new 1200 L microcarrier production line. The relevant technologies have obtained more than 100 patents and more than 30 articles about the technologies in international journals have been published. The core technology projects have obtained a number of national-level project support and applications.

Scan the QR code to read on your phone

-

Phone

- Service hotline+86 400-012-6688

-

E-mail

- E-mailwangal@cytoniche.com

- TOP

京公网安备 11010802037749号

京公网安备 11010802037749号