Solution for Large-scale Production of Cell-Cultured Meat — Efficient Cell Expansion and Modular Bio-assembly based on 3D Porous Gelatin Micro-carriers

- Categories:Company News

- Author:

- Origin:

- Time of issue:2022-06-23

- Views:0

(Summary description)Recently,aresearchgroupledbyProfessorDuYa'nanfromTsinghuaUniversitySchoolofMedicine,incollaborationwithBeijingCytoNicheBiotechnologyCo.,Ltd.,publishedaresearchpaperinBiomaterials[IF:12.479]entitled"En

Solution for Large-scale Production of Cell-Cultured Meat — Efficient Cell Expansion and Modular Bio-assembly based on 3D Porous Gelatin Micro-carriers

(Summary description)Recently,aresearchgroupledbyProfessorDuYa'nanfromTsinghuaUniversitySchoolofMedicine,incollaborationwithBeijingCytoNicheBiotechnologyCo.,Ltd.,publishedaresearchpaperinBiomaterials[IF:12.479]entitled"En

- Categories:Company News

- Author:

- Origin:

- Time of issue:2022-06-23

- Views:0

Recently, a research group led by Professor Du Ya'nan from Tsinghua University School of Medicine, in collaboration with Beijing CytoNiche Biotechnology Co., Ltd., published a research paper in Biomaterials [IF:12.479] entitled "Engineered meatballs via scalable skeletal muscle cell expansion and modular micro-tissue assembly".

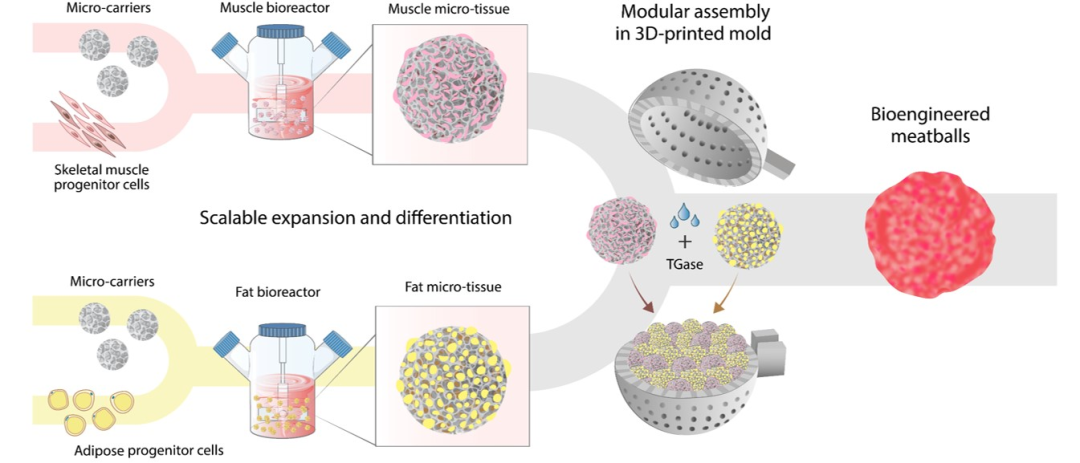

The study revealed that muscle and fat progenitor cells can be rapidly expanded, differentiated, and matured on the edible 3D porous gelatin miniature bio-scaffolds (microcarriers). Bio-assembly technology can be used to further assemble muscle and fat micro-tissue materials into centimeter-scale meatball analogues.

【Background】

Recent advancements in cell-cultured meat technology have the potential to revolutionize food production in the near future. Cell-cultured meat has substantial nutritional, health, safety, and environmental benefits over conventional meat. In recent years, the field of cell-cultured meat has attracted an increasing number of scientists and investors. The emergence of this technology provides a new option to shift the existing paradigm of meat consumption, which is in line with the goal of low-carbon, green, and sustainable social development. However, numerous theoretical and technical obstacles remain, especially in terms of gaining access to muscle cells economically and at scale, and bio-engineering of them into food.

At present, using a two-dimensional culture approach, the yield of cell-cultured meat is still poor and the cost is high, which is insufficient to produce substantial amounts of muscle tissue for commercialization. Therefore, the development of efficient, safe, and low-cost animal cell culture technology, the construction of growth environment for animal muscle tissue, and large-scale production in bioreactors will become the key issues in the industrialization of cell-cultured meat.

This article introduces a method for the efficient expansion and differentiation of muscle and adipose stem cells based on an edible porous gelatin miniature bio-scaffold (micro-carrier) in combination with spinner flask bioreactors. Muscle and adipose micro-tissues are modularly assembled using 3D-printed mold and are ultimately processed into centimeter-scale engineered meatballs by food engineering technology, aiming to provide a fresh perspective and technical support for the research and industrialization of cell-culture meat.

【Study Content】

▲Figure|From scalable cell expansion to tissue engineering of cultured meat

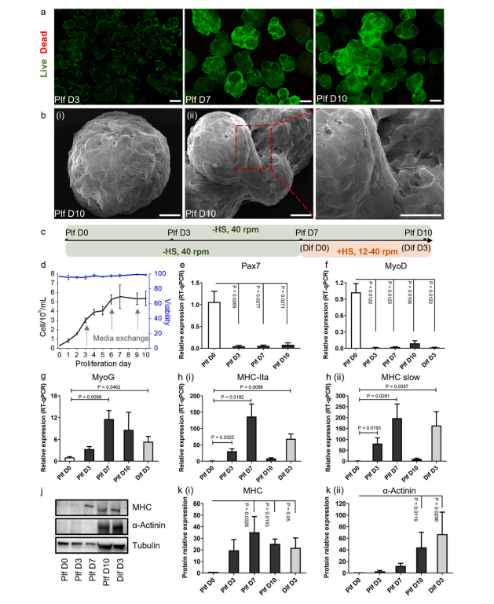

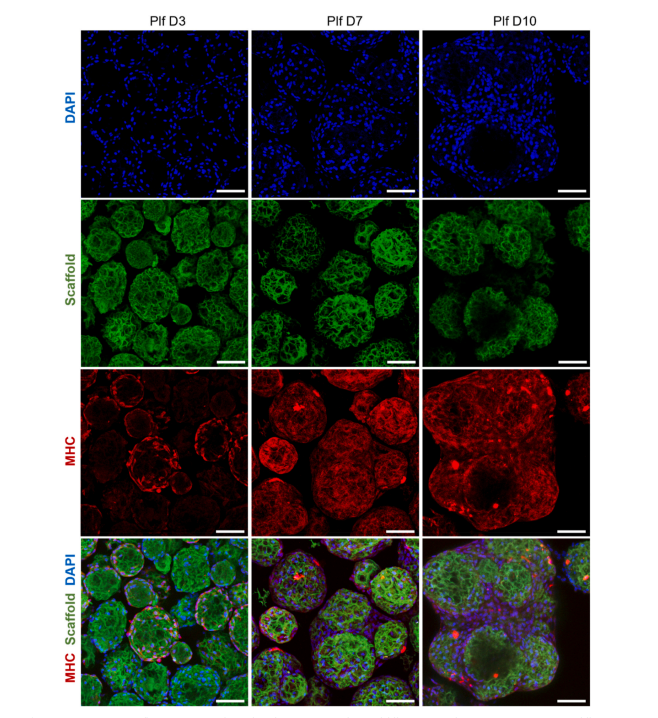

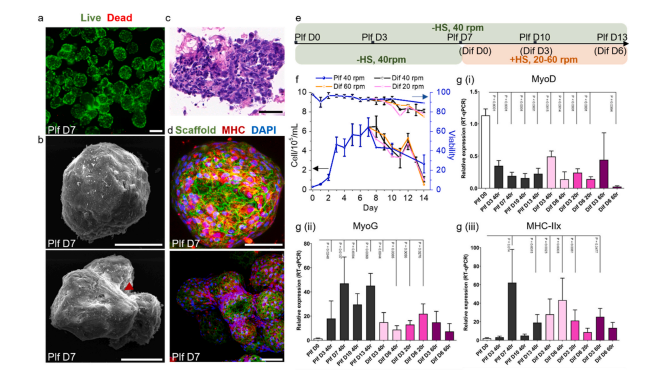

1. Proliferation and differentiation of porcine stem cells

The study showed that the application of CytoNiche's 3D FloTrix® micro-carrier in combination with spinner flask bioreactors enabled scalable and efficient expansion of porcine muscle stem cells in vitro, with about 18-fold expansion within 7 days. In the absence of the conventional myogenic differentiation-inducing additive (e.g. horse serum), muscle stem cells in 3D micro-carrier culture system could spontaneously differentiate towards mature skeletal muscle cells. As seen in the figure, the expression of related gene and protein markers significantly increased during differentiation.

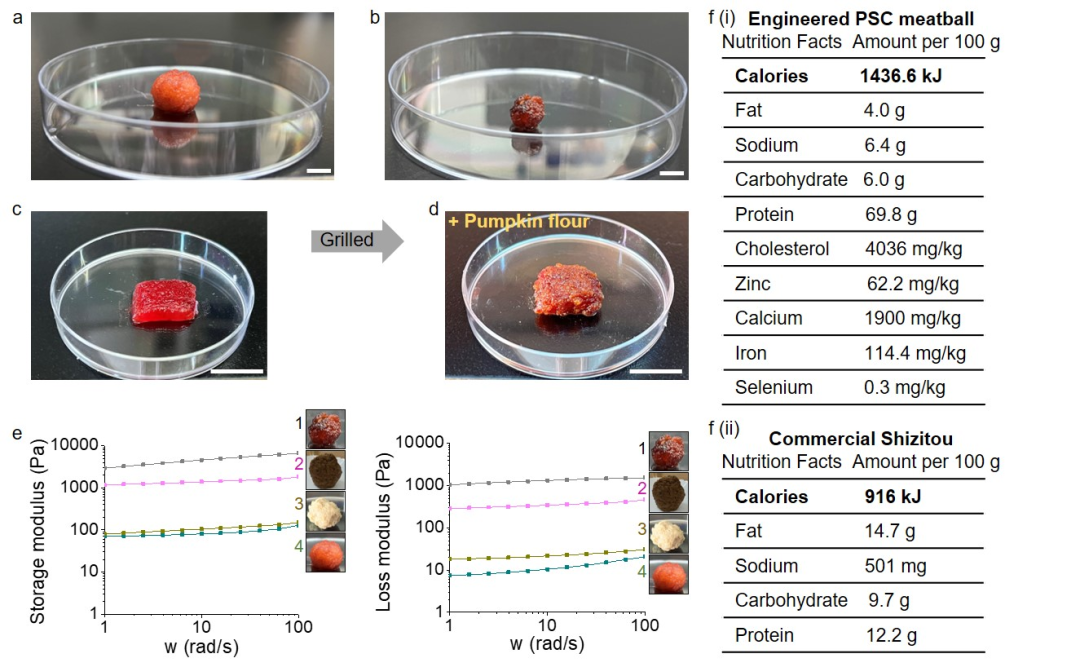

2. Engineered pork meatballs

In addition, the "micro-tissues" composed of cells and micro-carriers cultured for 7–10 days were added with transglutaminase as a tissue cross-linker, and the 3D-printed molds were used to print centimeter-scale ground meat analogues, such as pork meatballs and pork slices, from micro-tissues of several hundred microns. Moreover, we analyzed the nutritional composition of the meatballs, with 69.8% protein, 4% fat, 6% carbohydrates, as well as key essential minerals such as zinc, calcium, and iron. Compared with the purchased traditional "Shizitou", engineered meatball contained higher protein and lower fat content. Therefore, engineered meatballs can be a nutritious alternative for ground pork products.

▲Figure|The morphology of cell-cultured pork products before (a, c) and after cooking (b, d), as well as the comparison of hardness (e) and nutrition facts (f) between cell-cultured pork meatballs and those made from natural pork (Shizitou).

3. Proliferation and differentiation of murine adipocytes

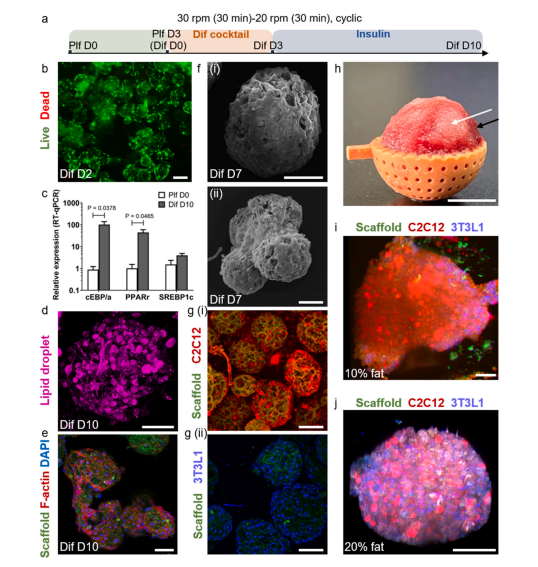

To investigate whether these edible porous micro-carriers was suitable for the expansion and culture of other types of skeletal muscle cells, we also selected the murine myoblast C2C12 cell line for dynamic suspension culture using the micro-carrier system. The results showed that, similar to porcine muscle stem cells, C2C12 not only proliferated efficiently in large numbers (21-fold expansion within 7 days) with 3D TableTrix® microcarrier culture system, but also formed mature skeletal muscle cells spontaneously without the addition of differentiation-inducing components.

Figure | Modulation of various events in the tumor microenvironment via exosomal communication

4. "Fatty and lean" meatballs

In addition, the 3D FloTrix® Microcarrier Culture System can also supported the expansion and differentiation of murine 3T3L1 pre-adipocytes. The differentiated fat micro-tissues were mixed with muscle cell micro-tissues in a certain ratio. Using 3D modular bio-printing technology, the "fatty and lean" engineered meatballs with tunable fat content can be created. Therefore, we can imagine that this cell-cultured meat technology will enable the customization of meat products in the future to meet the preference and needs of diverse populations.

【Conclusions】

The above findings suggest that a novel edible porous micro-carrier can be used as the scaffold system for cell-cultured meat production with the source of skeletal muscle cells or other types of cells (e.g. adipocytes). It has the following advantages when combined with spinner flask bioreactors for dynamic culture:

1. It can not only support scalable and efficient expansion of cells, but also conserve space, material, and human resources compared with the conventional two-dimensional culture;

2. In addition to supporting cell expansion, it allows cells to differentiate and mature spontaneously without the addition of differentiation-inducing components;

3. the approach of micro-tissue bio-assembly pushes the size of engineered meat from the conventional micron- or millimeter-scale to the centimeter-scale, which is one step closer to the dimension of real meat, laying the foundation for the industrialization of cell-cultured meat.

4. The proof-of-principle meatballs with tunable fat content also provides a fresh perspective and technical support for the construction of artificial organs using these building blocks, and helps explore more possible application scenarios of this technology in the field of biological tissue engineering.

【Research Team】

This study was conducted by Tsinghua University in collaboration with Beijing CytoNiche Biotechnology Co., Ltd.

Tsinghua University School of Medicine — Professor Du Ya'nan:

He has been innovating in the field of "Microtissue Engineering", with accomplishment in the theoretical elucidation and technological translation.

The 3D micro-tissue technology developed by the team can be used as an expansion and preparation platform, as well as a pharmaceutical delivery system of new-generation stem cell drugs, to innovate in vitro cell culture and regenerative medicine. It can also assist in establishing bionic physiological/pathological models for high-throughput drug screening and pathological mechanism research.

He has published more than 100 high-impact SCI papers (in Nature Materials, Nature Communications, PNAS, Science Advances, and other journals).

He has been approved and authorized 16 patents. In 2018, Beijing CytoNiche Biotechnology Co., Ltd. was founded to transform, apply, and commercialize of the patented micro-tissue engineering technology.

Beijing CytoNiche Biotechnology Co., Ltd.:

Led by the research team from Tsinghua University School of Medicine, and jointly founded by Tsinghua University through equity participation. CytoNiche focuses on building an original 3D cell "smart manufacturing" platform, as well as providing overall solutions for the 3D microcarrier-based customized cell amplification process, so as to address the pain points in the development of the global cell industry.

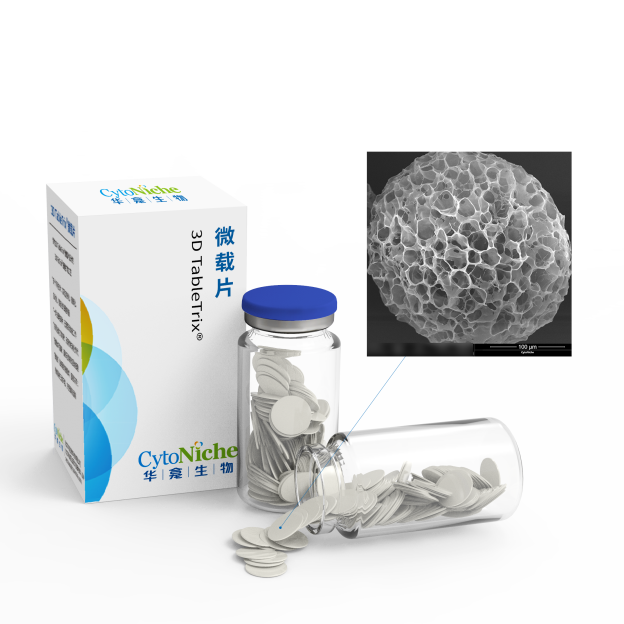

The core product, 3D TableTrix® Microcarrier Tablet (Micro-carrier), is independently innovative and the first pharmaceutical micro-carrier that is applicable to the development of cell therapy products. It has obtained the certificate of analysis from relevant authorities, such as the National Institutes for Food and Drug Control, and has obtained the qualification for pharmaceutical excipients from National Medical Products Administration (CDE approval registration number: F20210000003, F20200000496). Besides, the latter one has obtained the DMF qualification for pharmaceutical excipients from US FDA (DMF: 35481).

The products and services of CytoNiche can be widely used in the upstream process development of gene and cell therapy, extracellular vesicles, vaccines and protein products. At the same time, it also has broad application prospects in the fields of regenerative medicine, organoids and food technology (cell cultured meat, etc.).

The company has 5000 square meters of R&D and transformation platform, including more than 1000 square meters of CDMO platform, 4000 square meters of GMP certified manufacturing platform of, and a newly built 1200 L micro-carrier production line. The relevant technologies have obtained more than 100 patents, and more than 30 articles about the technologies in international journals have been published. The core technology projects have obtained a number of national-level project support and applications.

【Materials and Equipment】

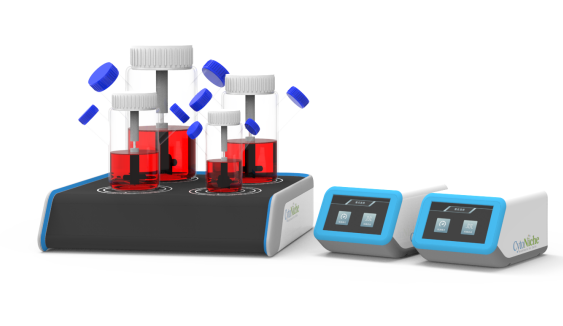

The 3D porous gelatin microcarriers, spinner flask bioreactors, and other supporting materials and equipment applied in this study are all established commercial products from CytoNiche.

▲3D TableTrix® Micro-carrier (porous gelatin micro-carrier)▲3D FloTrix® miniSPIN Bioreactor (spinner flask bioreactor)▲3D FloTrix® vivaSPIN Bioreactor (spinner flask bioreactor)

【Original Link】

Scan the QR code to read on your phone

-

Phone

- Service hotline+86 400-012-6688

-

E-mail

- E-mailwangal@cytoniche.com

- TOP

京公网安备 11010802037749号

京公网安备 11010802037749号